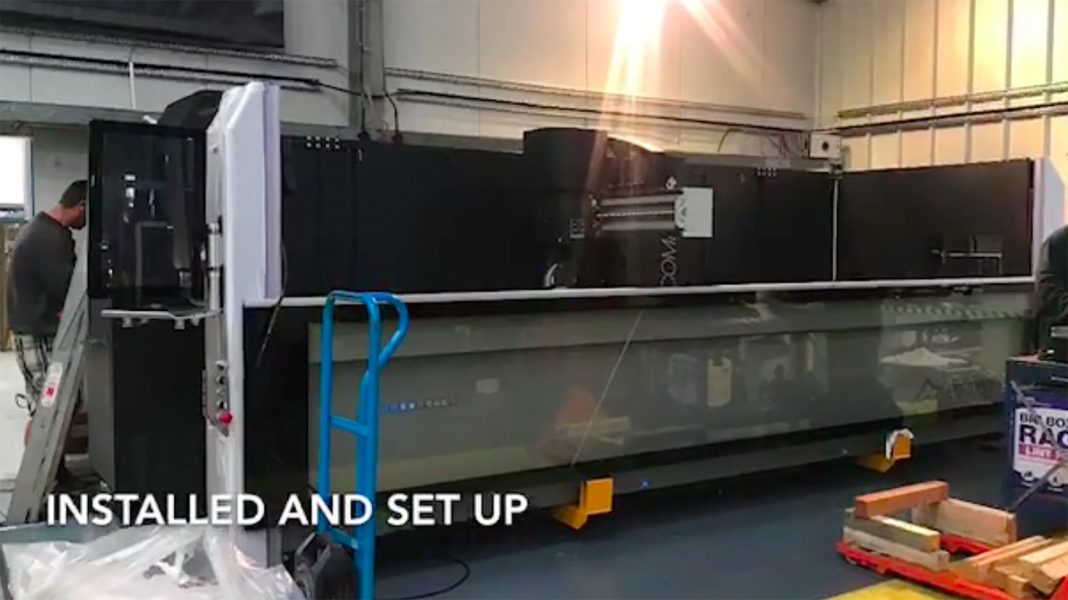

The installation of the first Emmegi Comet R4I model in the UKhas been charted in a time-lapse video following the arrival of the 5-axis CNC machine at the factory of Victorian-style aluminium greenhouses and conservatory manufacturer Alitex in Hampshire.

Alitex already has ten Emmegi machines installed, ranging from a single head saw supplied way back in 2002 to a five axis Satellite XT machining centre supplied in 2016. This time, driven by the renewed focus on gardens and outdoor space, the company needed to expand its machining capacity still further.

The company chose the new Comet R4I, which is the latest version of the 5-axis, 4m Comet R4 machining centre. The I stands for ‘Independent’ because it offers independent positioning of the motorised vices. While the electrospindle is operating in one area, the machine can be automatically setting up the vices ready for machining in the next, saving significant amounts of operator time.

The R4I further optimises efficiency by machining from -15° to 90° on the horizontal axis and a full 360° on the vertical axis. It has a 12-piece tool magazine with guaranteed fast changeover and a mobile worktable to make for easy loading and unloading of bar lengths up to 4m.

Emmegi sales manager Andrew Jones explained: “Some of the Alitex team were originally scheduled to travel out to Italy to carry out the FAT test for themselves, which was obviously not possible under the current restrictions, but we worked out the next best thing.”