Haffner has unveiled two new PVC-U automated machining centres, which are due for market release soon.

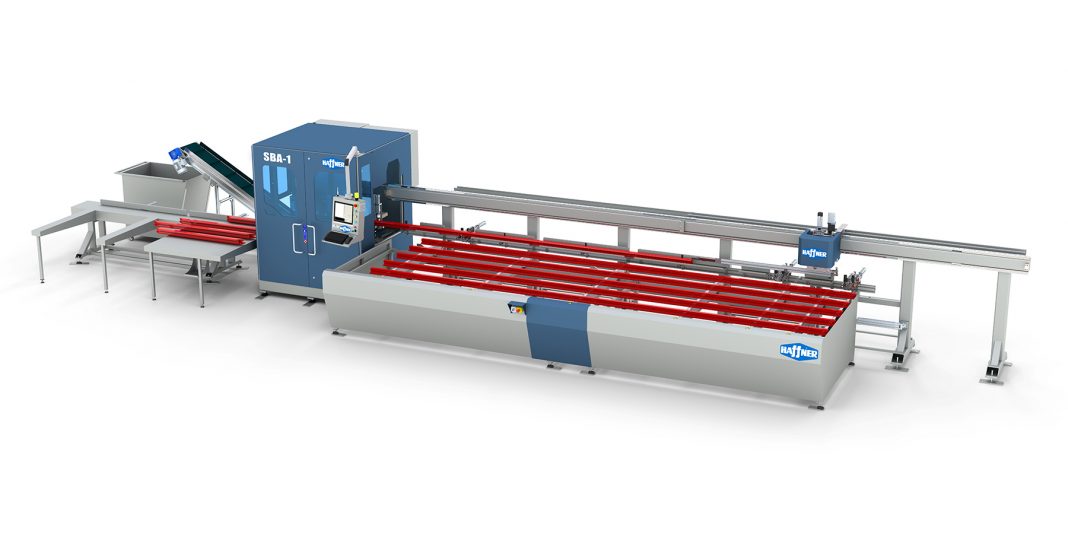

The new SBA-1 Machining Centre has been designed to assist the smaller fabricator to compete in a market where labour prices are high and skilled workers are hard to find. It will allow fabricators to cut and route between 300-400 windows per week with just one operator.

The SBA-5 Machining Centre has all the attributes of the SBA-4 including additional servos to further increase routing times on both door profiles and night vents.

CEO Dave Thomas said: “Like all our machines, they have been designed to deliver high levels of automation throughout the fabrication process, speeding up production, improving product accuracy and turbo-charging efficiency.”

Dave commented: “The benefits of automating window and door fabrication have always been clear when boosting efficiency and productivity on the factory floor. The two new machines are suitable for fabricators at all levels looking to scale production output as fluctuating demand dictates with minimal resources.”