Liverpool-based aluminium fabricator Door and Window Systems (DAWS) is continuing to increase productivity with the recent installation of its fifth new Kombimatec machine in 18 months.

The latest is an AMC308 Automatic CNC Machining Centre, coming closely after a DGS500 Electronic Double Mitre Saw, CC120 Power Crimper, AFV362 Variable Angle End Miller and MGS460 Upstroke Mitre Saw.

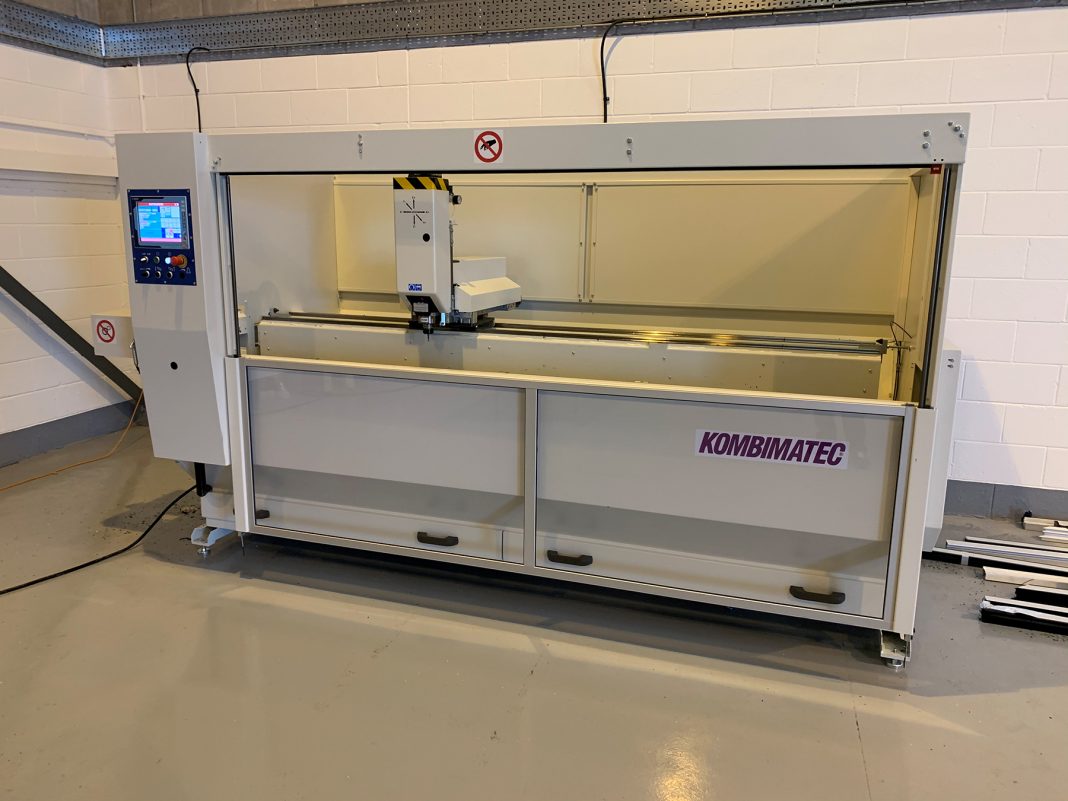

The AMC308 machining centre was developed by Kombimatec for both aluminium and PVC-U profiles. Manufactured with a solid steel construction using high quality components, it incorporates advanced CNC control with CADCAM software that provides exceptional levels of precision and reliability during production. DAWS version comes with a 5HP electro-spindle inverter driven to 180000 rpm, closed loop servo driven system, automatic safety guard, and voltage monitor for electrical protection.

Dave Harrison, director at DAWS, said: “The AMC308 is a benchmark for fabricators establishing a window fabricating business in our industry. Previously we used manual copy routers to complete the prep work and it got to the point where we had one person working the router all day. From a cost point of view this machine will easily pay for itself in 2 years. For us, the main benefits are accuracy and efficiency. The CNC has enabled us to increase our output massively.”

Kombimatec director David Parsons added: “Like many of our loyal customers, DAWS prides itself on supplying the best quality, premium door and window products on time every time – and Kombimatec are proud to continue to provide the solutions to help them achieve that.”