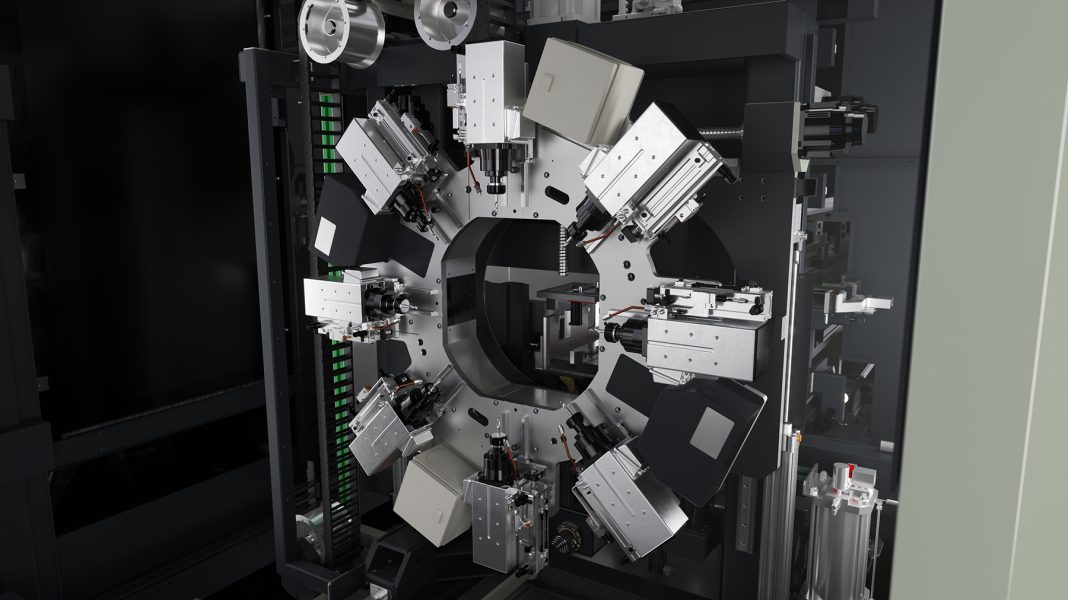

Emmegi has introduced the +Quadra as the next generation of its 20-axis modular Quadra CNC, which can cut, drill and machine in a single operation.

The new +Quadra with its 360° rotary based milling, drilling and tapping on four faces of the profile and 360° rotary cutting blade does everything that the original Quadra can do and more.

As previously, there are four high frequency electro spindles for +Quadra L0 and six and eight for +Quadra L1 and +Quadra L2, all housed within a soundproofed cabin. Among new features are dynamic counterblocks which can be programmed to recognise the profiles being selected and automatically adjust and set the vices without the need to set up individual counterblocks each time.

There is also a new head and tail end milling module and cutter unit with variable rotation speed up to 8000rpm and an automatic labelling module which can position the label on 3 sides of the profile.

There are new additions to the loading and bar feed system which allow for extended unmanned cycles. This includes a profile lifting system which picks up the profile and automatically transfers it to the operating section, and the option of a high capacity belt loading magazine which can accommodate upwards of 8 profiles at a time. There is also a high capacity unloading magazine which automatically aligns all the machined pieces from one section before they are transferred to the unloading belt and, with 4m, 7.5m or 9m options, allows the entire volume of profiles from the loading magazine to accumulate without any operator intervention.

The machine can be seen in action at: https://www.youtube.com/watch?v=f-Y5UkNMbKQ