John Fredericks has sped up fabrication, increased capacity, and optimised workforce structure with the addition of a fully automated frame welding and corner cleaning line.

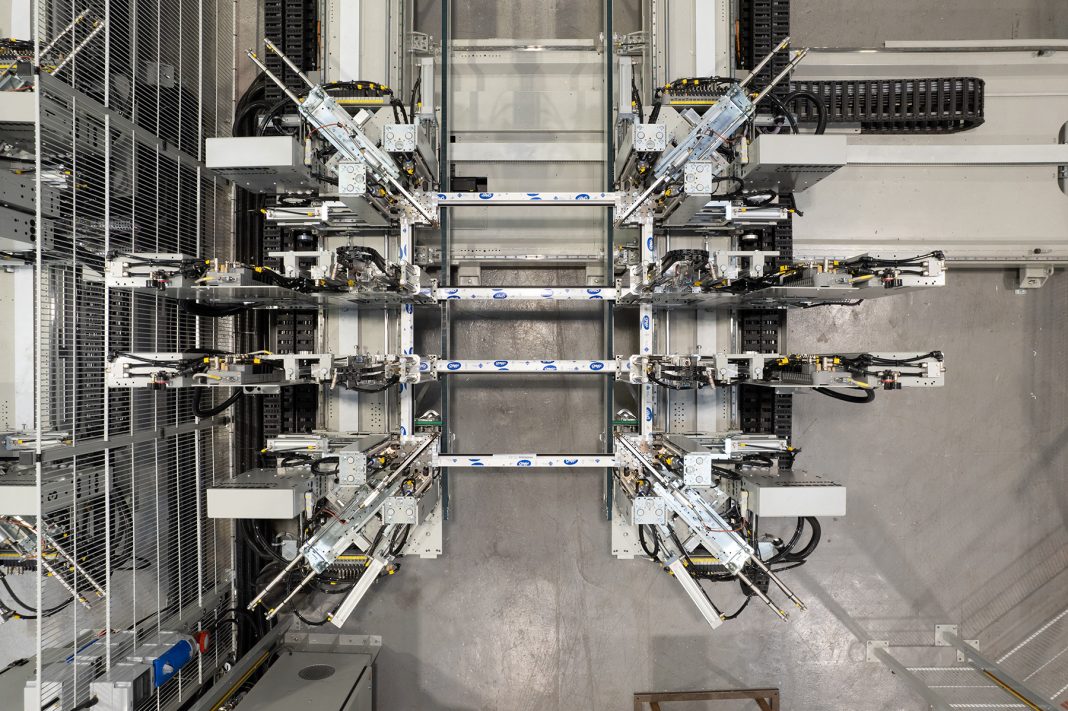

MD Mark Dicconson said: “We’ve now got an Urban SV 800 automatic corner cleaner fed by two Urban AKS 6600 8-headed welders, all on a fully automated conveyor system, along with a transfer table and cooling racks for foiled products.

“Operating through barcode recognition, the system has been designed to recognise different profiles, whether foiled or not, and automatically enter the profile size, thus removing the chance of human error. This enables absolute accuracy and consistency, and increases output.”