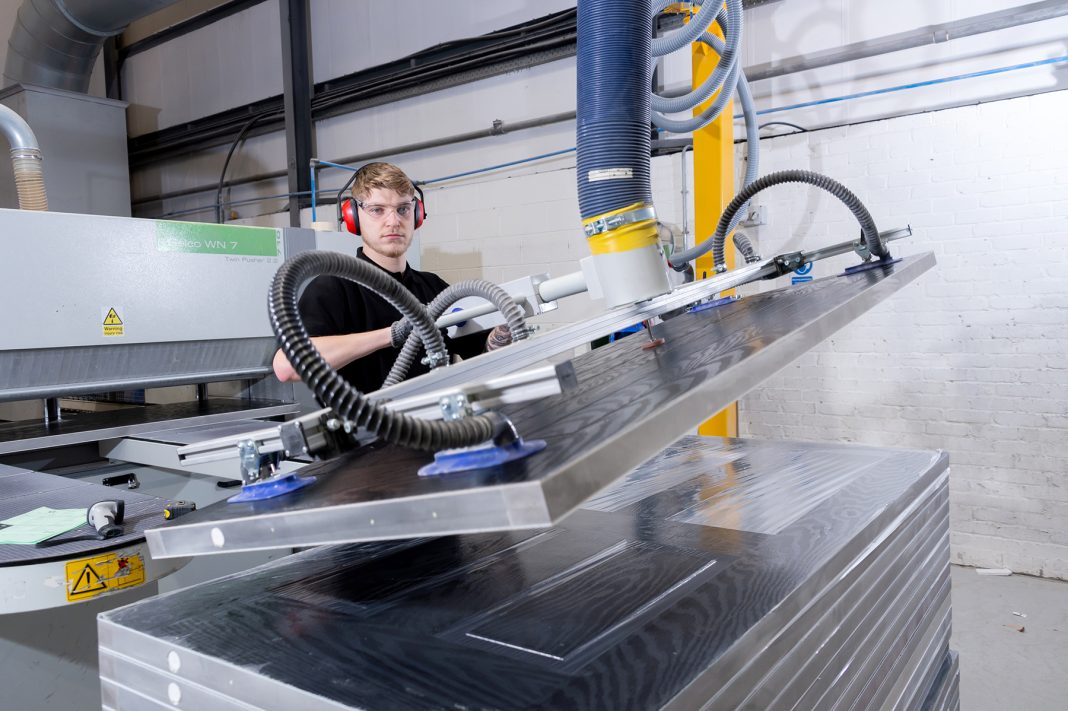

DoorCo is investing £750,000 in its prepped door supply service by unlocking capacity with a full redesign its factory in Macclesfield.

MD Dan Sullivan said: “The manufacturing or prepped door side of DoorCo, which now makes up 30% of our sales, has evolved into an all-access service for all our customers, regardless of size, type and requirements of the varying markets they deliver into. Requirements in the retail sector can massively differ from the commercial new build and social housing sectors. It’s essential DoorCo can support its customers, no matter how much prepping support they need and in what volume.

“We cater for any specification and can prep for any lock; any hinge; open in; open out; edgeband painted or not. We can paint to any colour, whether from our Approved DoorCo PAiNT range or to match any RAL, using our three state-of-the art paint lines, and we can pre-glaze doors with DoorCo Approved (and some exclusive) GLAZiNG designs in either our own FLiP glazing cassette system, or Inox cassettes. We also support our Distribution customers – larger fabricators with in-house manufacturing facilities – with additional services, like painting, prepping for bespoke orders or to support capacity.

“Customer demand has driven this change within DoorCo and to ensure we continue to deliver the innovative service they need, we are kick starting a new round of investment with £750k going into improving our manufacturing facility.

“The project is being led by our new head of manufacturing, Aaron Williamson. Aaron joined DoorCo last year as part of our senior leadership team, having spent 13 years working in manufacturing across different industries in the UK and USA. Aaron’s experience means he offers a totally new perspective on manufacturing capabilities to DoorCo and has supported us in developing a plan to unlock capacity and deliver greater resilience for the future of the business.

“Over the next couple of months, Aaron and his team will be undertaking a full redesign of our manufacturing facility that will streamline production, relieve any bottlenecks, create space for extra machinery, and ultimately, unlock more capacity.

“From relatively humble beginnings, DoorCo is now a multi-site business, with state-of-the-art manufacturing and warehousing facilities that total 95,000 sq.ft, that are well-stocked with a comprehensive range of composite door components, as celebrated in our recent G22 win as Component Supplier of the Year. We understand what our customers need and our independent status means we can flex, adapt and invest, and no matter what the sector continues to face, we are committed and ready to support our customers in the best way we can.”