HWL Windows has said that it is in the unique position to be able to offer four Timberwelded flush systems that are Part L ready, ahead of when the new standard comes into effect in June.

“We make four different flush casement systems”, explained managing director Mark Haley, “This includes Residence Collection R9, R7 and R2, each of which meets new build – as well as home improvement Part L requirements – in a Timberwelded and non-glass-bonded flush casement window.

“We also offer the new Kömmerling Flush casement, which is also available in a Timberwelded 90° joint, and as an ultra-energy-efficient and six-chamber system, comfortable achieves a u-value of 1.2 W/m2K – without having to go to a triple-glazed unit.”

Mark continued: “We’ve built our reputation as a specialist manufacturer of Residence Collection product but we see the Kömmerling Flush Casement as a very important addition to our range because it gives us and our customers reach into a broader sector of the market.

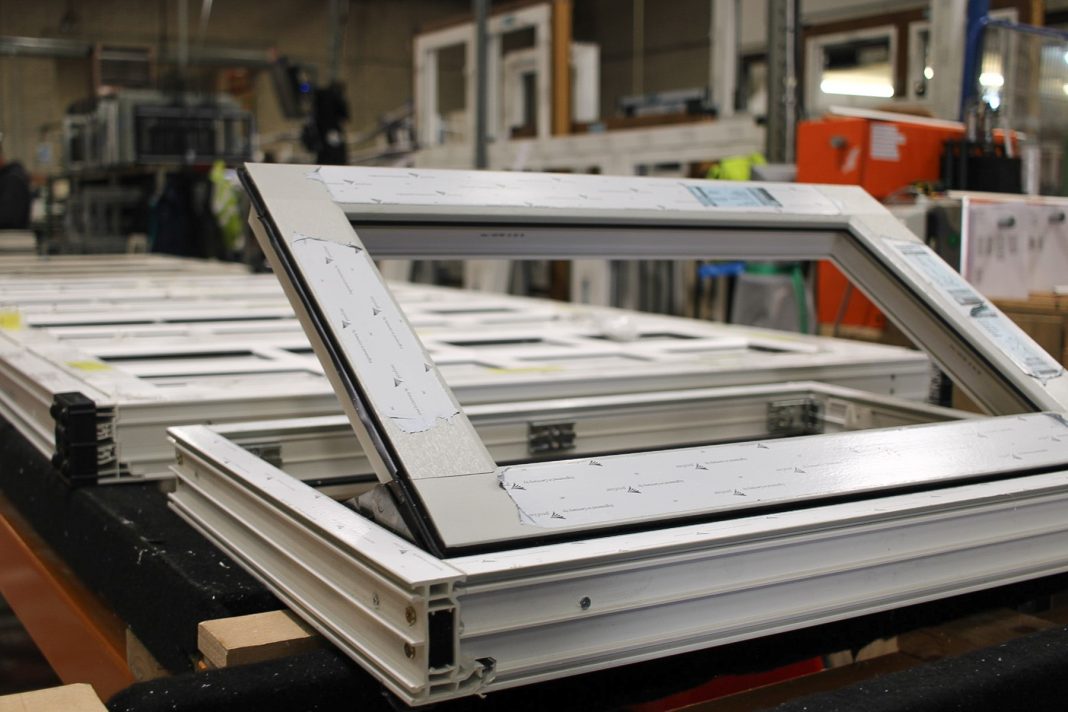

“We manufacture it using the same Timberweld technologies that we developed in the manufacture of R9 to create that traditional 90° timber-like joint in a welded – not mechanically jointed window.”

HWL pioneered the development of non-glass bonded Timberweld R9, making it easier to handle and significantly reducing costs for installers, and now offers a unique Timberweld Residence Collection open-in door – giving its customers the opportunity to upsell a matching Residence window and door package to homeowners.

He added: “It’s technology we’re now applying to the Kömmerling flush. We’re the first – and we believe currently the only fabricator – manufacturing it with a Timberweld finish. It’s something which we know delivers real commercial advantage for our customers.”