Pilkington owner NSG Group and University of Cambridge are working together to find new ways of printing conductive materials onto wide areas of curved glass surfaces.

Dr Su Varma, R&D incubator academic programme director at the NSG Group European Technical Centre, said: “This is an exciting project that has the potential to extend the boundaries of glass’ use in car manufacturing and building design.

“It allows high-tech applications of glass to not be limited to flat surfaces, expanding opportunities for architects, while revolutionising the role that glass can play in vehicles.

Currently, conductive materials can only be effectively printed onto flat glass surfaces. If successful, this innovation is set to enable the printing of metallic nano inks at high precision across curved glass, introducing new applications for glass in automotive and architectural sectors by increasing the potential functionality of glazing. New uses include helping detect pollution, incorporating heating elements or as digital signage.

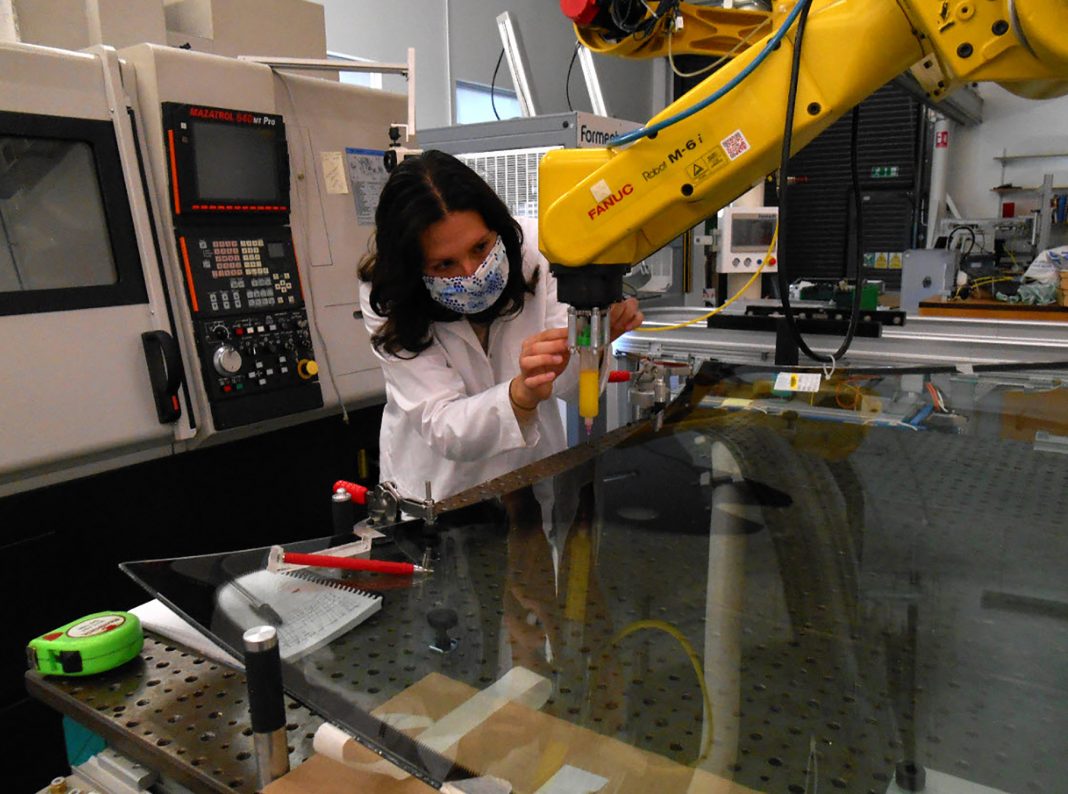

For the first phase of the research, the partners are using virtual reality to model and design a laboratory that uses robotic technology to print the conductive materials onto curved glass surfaces. Using robots, printing the nano inks will be done with high precision and speed, while accounting for the curvature of the glass.

Dr Ronan Daly, head of FIAM and senior lecturer at the University of Cambridge, said: “Smart technology applied to glass has the potential to perform a number of important tasks – from identifying the presence of bacteria on a hospital window to performing as a touchscreen display, for example.

“Conductive materials can already be printed onto flat surfaces, and alongside the NSG Group we’re now overcoming the physical challenge of completing this for curved applications – this opens up new opportunities for designers to use glass technology to solve their modern design challenges.”