Bystronic at Vitrum

The Bystronic glass group is exhibiting at Vitrum 2011 in Milan.

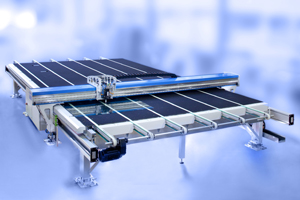

At stand L22 in hall 13 the customers will get an overview about the latest machinery for architectural glass cutting, for the manufacturing of insulating glass and laminated glass, for the preprocessing of automotive glass and for the production of photovoltaic modules.

Speed’cut is the new float glass cutting table for the dynamic shape cutting with maximum precision. With a speed of up to 300m/min and an acceleration of up to 6m/sec2 the machine guarantees a quick processing of cutting plans including rectangles and shapes.

The low weight of the cutting bridge leads to a 20% reduction in energy use for acceleration and braking. Multiple cutting oil circuits for different glasses as well as an automatic tool changer make operational manual interventions almost unnecessary.

Eco’convect is a pre-nip system for the manufacture of high quality laminated glass of all kinds. It is a completely new heating and press system that works with significantly reduced cycle times while being suitable also for shaped formats and multifunctional glasses.

The eco'convect allows highly-reflective, coated glasses to be processed together with float glass as with strengthened glass and tempered glasses. The new core of the laminated glass production processes all common film types such as PVB, EVA and SentryGlas (by DuPont) and easily creates complex glass constructions. The Eco’convect consumes up to 50% less energy than comparable machines.

Speed'sealer is a high-speed sealing machine for insulating glass units. The new machine seals windows and facade elements at a maximum flow rate, while offering the highest application speed. It is possible, even with different production conditions, to actively and consistently mix the two sealant material components, thanks to a dynamic mixer. The Speed'sealer operates both quickly and precisely. The machine seals double and triple insulating glass units at high-speed. This is achieved regardless of the sealing material selected, variations in material quality or temperature, or even straight after production commences.