Improving and cost cutting

Investing in products such as plastic thermal reinforcements can cut down on fabrication costs, increase profit, and still exceed the criteria set down by the revised building regulations, claims Synseal.

Investing in products such as plastic thermal reinforcements can cut down on fabrication costs, increase profit, and still exceed the criteria set down by the revised building regulations, claims Synseal.

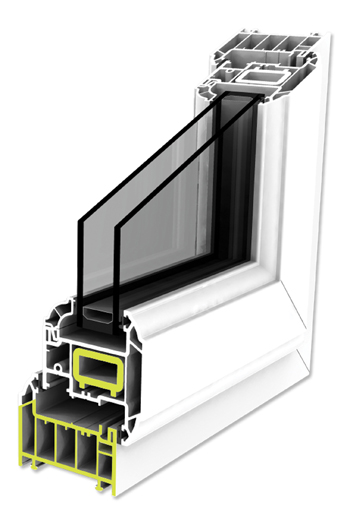

The systems supplier has developed a fully approved to BS7950 & BS6375 range of PTRs for Legend, SynerJy and Shield profiles, which are made from 100% recycled material and have been designed to make windows more energy efficient than those reinforced with steel.

Other advantages over steel for the fabricator include: no corrosion problems; price stable; less expensive; better screw retention and improved weld integrity, especially when welded into cruciforms. They also make the window lighter, easier and faster to fit for the installer, and makes the entire PVCU frame 100% recyclable.

“By using Plastic Thermal Reinforcements from Synseal in their frames, fabricators will make the entire window more energy efficient, which brings other benefits,” Tim Armitage, Synseal’s sales director, said. “For example, the glass units may not have to rely on expensive low-iron glass to achieve 1.6 W/m2K U-value, or a Window Energy Rating of a C (the minimum criteria laid down by the building regulations), which puts them ahead of the competition.

“Best results can be had when used in conjunction with Synseal’s new range of multi-chambered intermediate outer frames – designed for optimum thermal efficiency in a practical ‘plaster line friendly’ installation. These products can save up to £5m2 in glass costs.”