INNOVATIVE NEW PVC-u THERMAL INSERTS FROM EUROCELL OFFER UP TO 25% GLAZING COST SAVINGS

INNOVATIVE NEW PVC-u THERMAL INSERTS FROM EUROCELL OFFER UP TO 25% GLAZING COST SAVINGS

Eurocell has launched an innovative new range of recycled PVC-u Thermal Inserts for window profiles, which offer better fabrication processes, improved thermal performance and up to 25% cost savings on ‘A’-rated window glazed units*.

Cost savings are achieved because the use of PVC-u Thermal Inserts avoids the need for more expensive low iron glass. Performance modelling and extensive trials have demonstrated that 4mm standard float glass can be used with the thermal inserts whilst still achieving an ‘A’ rating, because of the superior thermal efficiency of PVC-u over traditional steel or aluminium reinforcements.

Eurocell’s PVC-u Thermal Inserts are manufactured using 100 per cent recycled PVC-u, enhancing the sustainability of frames, reducing the carbon footprint of fabricators and offering another selling point to specifiers and consumers. Using thermal inserts also means that an entire window frame is recyclable – making it quicker and easier to re-use post-consumer windows.

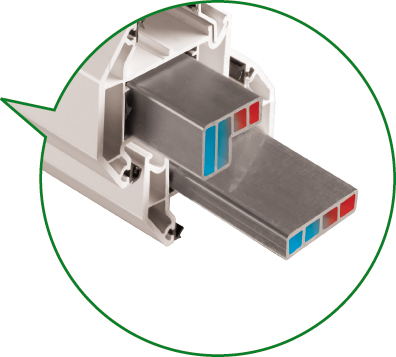

Thermal Inserts can be used as reinforcements in sashes and transom/mullions and can be mitred and welded into the frame, adding structural rigidity and ensuring a much more efficient and therefore lower cost fabrication process. Traditional steel and aluminium reinforcements require a separate cutting operation before being inserted into the profiles.

The new Eurocell profiles have been tested by the BBA to BS EN6375 and achieved impressive results. Casement windows can be fabricated up to a maximum height of 1500mm and 750mm wide for a single side hung window, a large increase over the previous maximum possible without the use of steel or aluminium reinforcements.

The multi-chambered design of PVC-u Thermal Inserts provides additional benefits over other non-metallic, hybrid and recycled reinforcements by creating what is essentially an eight-chambered profile in certain applications. This allows for a reduction in U-values without having to change glazing specification, along with up to a four point improvement in BFRC Energy Index performance (1 point = 1 kwh/m²/year). So windows with Eurocell PVC-u Thermal Inserts lose less energy.

Philip Parry, Head of Technical Standards at Eurocell Profiles, explains: “Over the last few years glass and spacer bar manufacturers have been developing products to improve the performance of the whole window and we felt it was time a systems company did something to reduce the cost of an ‘A’ rated window. By using PVC-u Thermal Inserts with our Eurologik system in conjunction with Thermalogik outer frames, we have managed to design out a costly element of ‘A’-rated windows to give fabricators a distinct advantage in the market.”

Martin Saunders, Sales Director at Eurocell Profiles, explains: “Our new recycled PVC-u Thermal Inserts offer a compelling case for fabricators. They perform better, are easier to use, are more sustainable and more cost-effective than the alternatives. It’s that simple.”

PVC-u Thermal Inserts are available for the ever popular Eurocell Eurologik chamfered and ovolo systems.

For information on the PVC-u Thermal Inserts visit the Eurocell website: www.eurocell.co.uk, contact customer services on 0800 988 3049, or email press@eurocell.co.uk

* Glazed unit cost savings based on a comparison of a standard A-rated window (4mm low iron external glass, 20mm SGG SWISSPACER® V spacer bar, 90% argon filled cavity, 4mm SGG PLANITHERM® TOTAL internal glass) and a Eurocell window using PVC-u Thermal Inserts, Eurocell Thermalogik outer frames with 4mm standard float external glass, 20mm SGG SWISSPACER® V spacer bar, 90% argon filled cavity, 4mm SGG PLANITHERM® TOTAL internal glass. Source: Solaglas Limited (November 2008).